Phenol Chemical Splash/Burn Phenol splash from eppendorf tube |  Trifluoroacetic Acid (TFA) – Case 1 TFA exposure from dropped vial |  TFA – Case 2 TFA spray from syringe/needle separation |  Paraformaldehyde Exposure Sudden gas release from vial |  Nitric Acid Spill on Forearm Exposure during container transfer |

Azide Explosion An ultrasonicator was used to dissolve sodium azide |  Nitric Acid Waste Bottle Reaction Incompatible waste mixing |  Presence of Triethylgallium Presence of TriethylgalliumBubbler tubing smokes on loosening |  Acetic Anhydride Spill A 4-L glass bottle slipped from grasp and fell to floor |  Acetic Acid Spill A glass bottle was dislodged from storage cabinet |

| Small Ethanol Fire A burning drop of ethanol leads to small fire |  Liquid Nitrogen Dispensing – Case 1 Liquid nitrogen spray from wild hose |  Liquid Nitrogen Dispensing – Case 2 Filling a dewar without proper PPE |

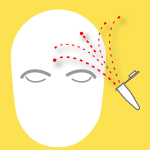

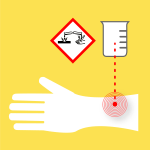

Phenol Chemical Burn

What happened?

Researcher #1 was isolating RNA from mouse spleen using an Eppendorf tube containing TRI Reagent® (phenol is a major component) and chloroform. The tube was manually shaken in an open lab when the lid popped open (probably due to pressure of chloroform vapor) and splashed liquid on to Researcher #1’s forehead. Researcher #1 wore a lab coat and nitrile gloves, but no eye protection. The splash immediately started running down the forehead towards the eye. With eyes rapidly closed, Researcher #1 began washing at a sink for ten (10) minutes and then removed contact lenses before seeking medical attention. Researcher #1 reported that the eyewash was not used because no one knew how to use it.

TRI Reagent® (Trizol®) Hazards

- Contains a high proportion of phenol (50-70 %), which is toxic and corrosive.

- Causes severe skin burns and eye damage.

- Rapidly absorbed through skin.

- When combined with chloroform, penetration of skin, clothing, and most glove materials is enhanced.

Injury

A superficial chemical burn was evident that ran from the forehead to the upper eyelid. Luckily, no phenol entered the eye, although it came very close (within one centimeter). If phenol had entered the eye then catastrophic eye injury would be a decidedly possible outcome.

Contributing Factors

- Casual attitude to PPE usage (particularly eye protection) persists in the lab.

- The SDS was not downloaded or read by researcher or by PI.

- Neither researcher nor PI was aware that TRI Reagent® contains phenol and that it is toxic and highly corrosive.

- No SOP was available for safe use of phenol.

- There was a lack of awareness on how to use the eyewash.

- Using contact lenses in lab could have exacerbated eye injuries.

Corrective Actions

- Train personnel on how to use the eyewash station.

- Create SOPs for phenol and other hazardous materials.

- Make available EH&S’ Phenol Safety Fact Sheet and SDS to be available to personnel, read, and understood.

- Distribute EH&S’ Eye Protection Fact Sheet and prohibit contact lenses in the lab.

Quick Tips

- Use splash goggles in phenol-chloroform extraction procedures. Note: Safety glasses are NOT appropriate for splash hazards — chemical splash goggles must be worn.

- When tubes are shaken, grasp tube in such a way as to cover top and prevent possibility of splash if top pops off. This is especially important if tube contains volatile solvents which may generate pressure. Consider using screw-top tubes.

- Shake tubes behind a fume hood sash, not in the open lab.

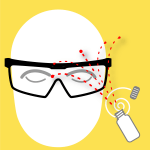

Trifluoroacetic Acid (TFA) – Case 1

What happened?

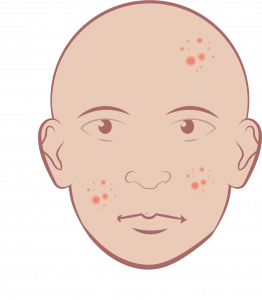

Researcher #2 was withdrawing trifluoroacetic acid (TFA) from a small vial into a syringe in a fume hood, holding it up behind the glass sash, which was open about a foot. The vial slipped and fell; on striking the fume hood work surface it did not break, but landed at an angle such that liquid splashed out upwards and on to Researcher #2’s face. Luckily, no splashes penetrated behind the safety glasses. Researcher #2’s eyes and face were rinsed at the eyewash station for at least ten (10) minutes. Researcher #2 reported a burning sensation and white patches and swelling appeared where the acid had contacted on the face. Washing was continued for thirty (30) minutes with cold water, after which the individual was transported for medical evaluation. Researcher #2 was wearing a lab coat, disposable nitrile gloves, and safety glasses.

Trifluoroacetic acid (TFA) Hazards

Trifluoroacetic acid is highly corrosive and can rapidly cause severe burns. It is highly volatile and the vapor is an extreme irritant to eyes and the respiratory system, and is harmful if inhaled.

Injury

Multiple chemical burns on the face which healed without scarring; no eye involvement.

Contributing Factors

Safety standards in the lab were assessed as generally good, and the lab personnel and PI responded promptly and appropriately to the incident.

- No formal records were maintained for training on specific lab procedures.

- Labelling of hazardous materials lacked hazard warnings. Clear labeling must incorporate the chemical name and hazard information (e.g. “trifluoroacetic acid, CORROSIVE”).

- Safety glasses were worn, whereas goggles are the correct choice for splash hazards.

Corrective Actions

- Safety glasses are NOT appropriate for splash hazards; chemical splash goggles must be worn.

- PI will keep internal safety training records.

Quick Tips

- Wear properly fitting chemical splash goggles when handing eye-hazardous liquids. Wear a face shield over goggles if handing substantial quantities of corrosive liquids, or if handling under conditions of raised splash hazard.

- Disposable gloves may be penetrated by high concentration TFA, or TFA in organic solvents. If thin gloves (disposable nitrile or polychloroprene) must be used on grounds of dexterity, then double glove and be sure to change gloves quickly if they are splashed.

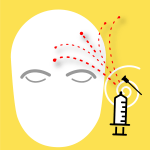

Trifluoroacetic Acid (TFA) – Case 2

What happened?

Researcher #3 attempted to inject trifluoroacetic acid (TFA) through a rubber septum by means of a small (1 mL) plastic syringe and needle. The operation was performed in a fume hood with the sash down. The needle separated from the syringe and TFA sprayed upwards and backwards into Researcher #3’s face. Researcher #3 was not wearing eye protection. Researcher #3 rinsed face and eyes for fifteen (15) minutes at the emergency eyewash before seeking medical attention.

Trifluoroacetic acid (TFA) Hazards

Trifluoroacetic acid is highly corrosive and can rapidly cause severe burns. It is highly volatile and the vapor is an extreme irritant to eyes and the respiratory system, and is harmful if inhaled.

Injury

Minor irritation to the eye was fully resolved, which suggests that the amount of acid which reached the eye was very small (luckily). Due to the absence of appropriate eye protection and the highly corrosive nature of the acid which was splashed, this incident had considerable potential for serious and irreversible eye damage.

Contributing Factors

The researcher was wearing a standard cotton lab coat, gloves, but no eye protection.

Corrective Actions

- PI and lab members will modify SOPs to include mandatory use of safety goggles and other appropriate PPE when working with corrosive and/or toxic chemicals.

- PI will monitor PPE usage of lab personnel and enforce compliance.

Quick Tips

PPE appropriate to the hazards must be worn at all times. Indirectly vented goggles are appropriate for splash hazards whereas safety glasses are NOT appropriate for this type of hazard. For serious splash hazards (e.g., when using large volumes of acid), a face shield should be worn over goggles. PI should ensure personnel have individual access to goggles; EH&S can provide a sample.

Note: A fume hood sash is NOT a substitute for protective eyewear.

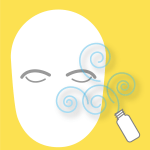

Paraformaldehyde Exposure

What happened?

Researcher #4 cracked open a vial of paraformaldehyde solution, and an unexpected evolution of gas sprayed some of the solution on to the face. Researcher #4 rinsed the face and eyes for two minutes at the emergency eye wash station and proceeded for medical consultation.

Paraformaldehyde Hazards

- Irritates eyes and the respiratory system, and is a carcinogen.

- Solutions of paraformaldehyde may release formaldehyde gas, a known carcinogen.

- Formaldehyde is also listed as a carcinogen in California Proposition 65.

Injury

No injuries were sustained.

Contributing Factors

- The researcher was wearing a cotton lab coat and gloves, but no eye protection.

- Work was performed outside of a fume hood at an open bench.

Corrective Actions

- Modify SOPs to include a mandatory use of fume hood and appropriate PPE while working with volatile high hazard chemicals.

- Include instructions that eyes should be rinsed for at least the recommended fifteen (15) minutes after a splash.

- All work and storage locations where carcinogens are handled are required to be labeled with appropriate signage.

Quick Tips

Use appropriate PPE (typically eye protection, gloves, lab coat) when working with hazardous chemicals. Safety goggles are mandated when a splash hazard exists, for example, when opening ampules; safety glasses are NOT appropriate for splash hazards.

Nitric Acid Spill on Forearm

What happened?

Graduate Student #1 was carrying out a nitration reaction inside a fume hood. In order to add nitric acid to the reaction, the student transferred the nitric acid to a beaker, then from the beaker to a graduated cylinder, and from there to the reaction flask. Within two minutes, the student experienced a tingling sensation on the forearm, and rinsed the area for 15-20 minutes. The student was wearing nitrile gloves, a Nomex lab coat, and safety glasses.

Nitric Acid Hazards

Nitric acid is a strong oxidant, and if the nitric acid concentration in methanol/ethanol rises above 10%, violent and potentially explosive reactions may ensue.

Injury

A superficial acid burn to the arm was sustained.

Contributing Factors

None identified. Safety management in the lab is very good.

Corrective Actions

For working with liquid corrosives and other splash hazards, the use of goggles is required. A face shield on top of goggles is recommended if large volumes are in use. For additional information, consult EH&S’ Eye Protection Fact Sheet and Eye Protection – Splash Hazard Fact Sheet.

Quick Tips

PPE appropriate to the hazards must be worn at all times. Indirectly vented goggles are appropriate for splash hazards whereas safety glasses are NOT appropriate for this type of hazard. For serious splash hazards (e.g. when using large volumes of acid), a face shield should be worn over goggles. PI should ensure personnel have individual access to goggles; EH&S can provide a sample.

Note: A fume hood sash is NOT a substitute for protective eyewear.

Azide Explosion

What happened?

Researcher #5 attempted to assist a colleague (who worked for a different PI) by synthesizing tert-butyl azide on a large scale, alone at night, without knowledge of permission of the colleague’s PI. The potentially highly hazardous synthesis was covered by a detailed written procedure (SOP), explicitly stating numerous safety precautions, which the researcher was not trained on and did not follow. Precautions included accurate temperature control, use of a blast shield, and slow addition of reagents. NOTE: The SOP had been provided to the colleague by the colleague’s PI, but with written instruction that the procedure was hazardous and not to be carried out except in the physical presence of the PI.

The synthesis called for the formation of a cold solution of hydrogen azide (volatile, highly toxic, highly sensitive explosive) in aqueous sulfuric acid. The azide source was sodium azide, and the procedure specifically noted that the sodium azide must be rendered free-flowing and completely free of lumps before addition, or it might not dissolve properly. Disregarding the SOP, Researcher #5 added agglomerated sodium azide, which failed to dissolve at a satisfactory rate.

Researcher #5 removed the open-neck flask of reaction mixture from the fume hood and placed it in a sonicator on the open benchtop, to try and speed the dissolution of sodium azide lumps. Immediately the sonicator was activated, the flask detonated in Researcher #5’s hand. Being in an unfamiliar lab, Researcher #5 failed to use the safety shower/eyewash right outside. Researcher #5’s lab was close by and Researcher #5 went there to wash eyes and body, before alerting the colleague at the other end of the building who then called DPS.

Azide Hazards

- Organic azides vary widely in their stability and explosive power, depending on the molecular structure. For alkyl azides, such as are used in “click chemistry”, the general rule is that the bigger the nitrogen to carbon ratio, the more explosive the compound is.

- Hydrogen azide (hydrazoic acid) is an extremely volatile liquid (boiling point 37 °C) which is a powerful and very sensitive explosive when pure; the vapor can also explode when present at a concentration of more than 15% in air or nitrogen. It is soluble in water, and the solution becomes less unstable on dilution. A ≤10% solution is regarded as safe to handle, whereas ≥20% solutions are explosively unstable. Addition of strong acid to sodium azide results in immediate formation of hydrogen azide in solution, with concomitant vapor evolution.

Injury

Serious injuries to both eyes from sulfuric acid and superficial cuts on hand and face were sustained. Eye injuries eventually healed, but took weeks before sight returned to normal.

Contributing Factors

- Failure to follow verbal and written instructions from PI

- No eye protection worn

- Modification of detailed written procedure for a hazardous experiment without knowledge or approval of PI

- Carrying out hazardous work alone after hours

- Working in a lab of another PI without permission or lab-specific training

- No blast shield

- Removal of flask of volatile, toxic, explosive solution from fume hood to open benchtop

Corrective Actions

- Re-iterate appropriate restrictions on performing hazardous work alone or out-of-hours.

- Re-iterate that personnel may not work in other PIs labs without the PIs knowledge and permission.

- Recommend that face shield plus goggles be used for work with potentially explosive materials in any significant quantity (e.g., > 50 mg).

- Blast shields must be appropriately employed when working with potentially explosive materials.

Quick Tips

PPE appropriate to the hazards must be worn at all times. Indirectly vented goggles are appropriate for splash hazards whereas safety glasses are NOT appropriate for this type of hazard. For serious splash hazards (e.g. when using large volumes of acid) and explosion hazards, a face shield should be worn over goggles and a blast shield should be employed. PI should ensure personnel have individual access to goggles; EH&S can provide a sample.

Note: A fume hood sash is NOT a substitute for protective eyewear.

Nitric Acid Waste Bottle Reaction

What happened?

Graduate Student #2 found a beaker labelled “7% nitric acid in ethanol” and poured the contents into a nitric acid waste bottle in the fume hood. The student did not recap the bottle. Within 30 seconds, a fierce reaction started in the waste bottle, evidenced by foaming, splashing, and brown gas evolution. The student immediately fully lowered the hood sash, called to other lab occupants to evacuate, and phoned DPS from outside the lab.

Nitric Acid Hazards

Nitric acid is a strong oxidant, and if the nitric acid concentration in methanol/ethanol rises above 10%, violent and potentially explosive reactions may ensue.

Injury

No injuries were sustained. It was fortunate that the bottle was uncapped and that the student immediately took the correct actions of closing the hood and evacuating. A capped bottle would have explosively burst and may have caused severe injury.

Contributing Factors

- No eye protection was used by the student.

- Even though nital (dilute nitric acid in lower alcohols) was a commonly used etchant in the lab, the student was not well aware of the dangerous reactions which may occur between alcohols and higher concentrations of nitric acid.

- The waste bottle was inadequately labelled. The label should have specified “Concentrated nitric acid waste. Oxidizer. Do not add organics.” Or, similar wording.

Corrective Actions

- SOPs for the safe handling and disposal of corrosive acids and etchant mixtures should be written. Personnel should be trained on SOP and PIs should retain signed internal training records.

- PIs should provide refresher training to all lab personnel on the appropriate use of PPE, and should maintain internal training records. PPE requirements should also be specified in SOPs.

Quick Tips

- Mixing nitric acids with organics is a “classic” and all-to-common cause of waste bottle explosions in laboratories.

- Use splash goggles instead of safety glasses when handling corrosives.

- Flammables and combustibles should not be stored in the same cabinet/cupboard as concentrated nitric acid or nitric acid waste.

- Dilute nitric acid in methanol/ethanol (nital) should not be stored.

- Potentially gas-producing waste required careful segregation. Vented caps should be employed.

Presence of Triethylgallium

What happened?

Triethylgallium was contained in a stainless steel “bubbler” attached to chemical vapor deposition (CVD) equipment. A researcher, working alone outside normal working hours, attempted to change the bubbler for a different one. On loosening a connector, smoke was emitted, signaling the presence of pyrophoric liquid in the pipe. The connector was immediately re-tightened, the lab was evacuated, and DPS was called.

Nomex lab coat and disposable nitrile gloves were worn at the time of the incident. No safety eyewear was used.

Triethylgallium Hazards

Triethylgallium is a highly pyrophoric liquid, i.e., it spontaneously ignites on contact with air.

Injury

No injuries were sustained, however, the incident is considered a “near miss” since the escape of the pyrophoric liquid from the tube would have led to serious consequences, including burn injuries.

Contributing Factors

- Performing hazardous operations alone and out of hours

- Possible error in following the bubbler change procedure. Failure to completely close the manual valve(s) all the way, may have allowed liquid to move up into the tubes when vacuum was applied

- Inadequate SOPs

- Lack of internal training records

- Insufficient PPE

Corrective Actions

- PI will conduct and document refresher training in accordance with the Annual Laboratory Safety Refresher Memo.

- PI will ensure that all lab personnel are appropriately trained, and if necessary, re-trained in all the hazardous laboratory operations they are individually approved to undertake. PI to retain internal training records.

- PI and research personnel will generate detailed, lab-specific SOPs covering hazardous laboratory operations.

- PI will institute and enforce effective restrictions on working on hazardous operations alone.

- PI will enforce correct PPE usage.

Acetic Anhydride Spill

What happened?

Researcher #6 was removing a 4 liter bottle of acetic anhydride from a flammable cabinet when the bottle slipped and broke on the floor. The researcher wore a lab coat and nitrile gloves, but no eye protection. Rather than immediately raising the alarm and evacuating the area, the researcher donned an (unapproved) half-mask respirator and attempted to neutralize the spill with a grossly insufficient mass of potassium carbonate (500 g bottle). While he was doing this, the liquid ran under the flammable cabinet and under the door behind the cabinet, forming a pool in the corridor.

An individual walking down the corridor slipped and fell into the pool of liquid, becoming contaminated on arms and legs. The individual suffered immediate symptoms of “burning” throat, eye irritation, and uncontrolled tearing. The individual washed in the restroom, then took a shower in a student accommodation next door, before being medically evaluated.

The PI was alerted to the situation and phoned DPS, who advised to pull the fire alarm to evacuate the building.

Researcher #6 who attempted to clean the spill suffered heavy eye exposure to the vapor. Researcher #6 was medically evaluated after evacuating the building. Eye irritation and redness resolved over a period of days.

The individual who fell in the liquid did not suffer any aftereffects.

Acetic Anhydride Hazards

Acetic anhydride is a corrosive organic liquid capable of inflicting serious skin and eye damage. It is volatile and the vapor is very acrid, causes irritation, and is harmful in sufficient concentration.

Injury

The only injury sustained was eye irritation lasting a few days. The individual who fell in the pool of liquid is especially fortunate to have escaped without burns or eye damage, potentially very serious.

Contributing Factors

- The lab had an excessive quantity of acetic anhydride relative to requirements (4 L bottle vs. 0.4 mL per experiment). Handling an oversized bottle increased the probability of an accident.

- Work practice was to syringe out 0.4 mL of acetic anhydride directly from the 4 L bottle every time an experiment was done. Correct practice is to decant a small working volume (20-50 mL) into a small bottle, only refilling this bottle from the stock bottle on an as-needed basis, which will be infrequent given the small volumes used.

- Laboratory personnel spent too long trying to remediate a situation beyond their training or resources, instead of immediately raising the alarm and blocking access to the area. NOTE: Any spill which requires respiratory protection is by definition beyond the capacity of lab personnel to safely tackle.

- An unapproved respirator was used outside of the USC Respiratory Protection Program. NOTE: It is not appropriate for personnel to use a respirator outside of the functions for which they were approved and trained.

- Lab personnel did not observe or consider the possibility that liquid was running under the flammable cabinet and under the door into the corridor.

- Inappropriate neutralization. It is immediately evident that 500 g of potassium carbonate is vastly insufficient to deal with 4 L of acetic anhydride. More importantly, however, remaining in the room to effect neutralization without proper resources, PPE, and training put the researcher at great risk.

Corrective Actions

- PI will ensure that students, especially new students, are familiar with emergency response procedures.

- PI will re-train personnel in emergency response, including: a) who to phone (1-2-3 Serious Injury Reporting Flyer — phone DPS first); b) when it is advisable to respond in-lab; and, c) when it is advisable to evacuate and leave response to Hazmat.

- Purchase appropriate quantities of hazardous chemicals and dispense via a small, correctly-labelled working bottle.

- Eliminate use of unapproved respirators.

Acetic Acid Spill

What happened?

Researcher #7 was putting away new chemicals in a cabinet under a fume hood when a glass bottle of acetic acid (ca. 100% concentration) inadvertently dislodged and fell out onto the floor. The bottle broke upon hitting the floor and was estimated as being 2-4 L in size. Researcher #7 was not wearing any PPE other than nitrile gloves. The lab personnel vacated the lab and shut the door immediately when the spill occurred and phoned EH&S.

Acetic acid vapor did not spread outside the lab and the building did not need to be evacuated. USC Hazmat responders were able to clean the spill without further problems.

Acetic Acid Hazards

Acetic acid is a corrosive organic liquid capable of inflicting serious skin and eye damage. It is volatile and the vapor is very acrid, causes irritation, and is harmful in sufficient concentration.

Injury

No injuries were sustained.

Contributing Factors

There was a lack of secondary containment for glass bottles.

Corrective Actions

- Wear appropriate PPE (i.e., lab coat, safety glasses/goggles, gloves) during all handling of chemicals.

- Provide secondary containment (i.e., plastic trays of sufficient volume to hold contents of bottles) for glass bottles of hazardous liquids.

Small Ethanol Fire

What happened?

Graduate Student #3 was sterilizing a 96-pin replicator by dipping into ethanol in a plastic tray, then removing and passing it through a Bunsen flame to burn-off the liquid. A burning drop of ethanol fell off the replicator into the tray, which immediately ignited, producing a flame about one foot high. The student used a standard laboratory dry powder fire extinguisher to extinguish the fire without difficulty. The student was wearing appropriate PPE, i.e., a flame resistant lab coat.

Ethanol Hazards

Ethanol is a highly flammable (Class 1B) and toxic liquid.

Injury

No injuries were sustained.

Contributing Factors

- Careless work practice (ethanol in combustible plastic tray too close to Bunsen, burning replicator held over ethanol tray).

- No SOP on safe Bunsen use.

Corrective Actions

The lab has already instituted a change of work practice. Ethanol flaming has been discontinued as a sterilization method and autoclaving is being used instead.

If use of the open Bunsen flame is deemed to be essential for technical reasons, then an SOP on safe Bunsen use must be developed by the lab, including strict guidelines on eliminating flammables and combustibles from the vicinity, and prohibiting leaving the flame unattended.

The Chemical Hygiene Plan (CHP) contains information on safe Bunsen use, based on the NFPA 45 standard.

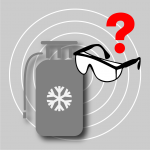

Liquid Nitrogen Dispensing – CASE 1

What happened?

The SOP for liquid nitrogen dispensing of open-necked dewars specified a minimum neck diameter to allow the diffuser on the end of the filling pipe to enter, and to allow for gas to exit. Two researchers unscrewed the diffuser and attempted to fill a non-SOP-compliant narrow neck dewar; furthermore, they turned the nitrogen flow up much too high. Reaction force from the resulting directional jet of liquid nitrogen blew the heavy filling pipe out of the Dewar and caused it to violently whip around spraying liquid nitrogen in all directions. One researcher ran to get help, and the other braved the danger and turned the flow off. The incident occurred outside. No PPE was worn by the researchers.

Hazards

- Direct contact with liquid nitrogen, cold vapor, or cold metal can freeze tissue and cause frostbite/cold burns.

- Boiling of liquid nitrogen produces large volumes of inert gas which can asphyxiate by displacement of oxygen.

- Heavy stainless steel tube whipping around might cause mechanical injury.

Injury

Luckily no. But there was extreme potential for severe injuries from being sprayed with liquid nitrogen or hit by the tube, including:

- Respiratory damage, from inhaling cold gas / liquid nitrogen spray

- Cold burns

- Eye damage

- Lacerations

- Asphyxiation – unlikely, since the event occurred out-of-doors, but not impossible if an individual was sprayed in the face.

Contributing Factors

- No training received on SOP for liquid nitrogen dispensing.

- Unauthorized modification of safety features (i.e. removal of diffuser).

- Lack of appropriate PPE.

Corrective Actions

- SOP was updated and re-sent to all personnel in the building.

- Facility management collected written acknowledgements from all users to confirm that they had received/read the SOP and agreed to follow it.

- Ensure lab personnel are aware of all SOPs and collect written receipts affirming adherence to SOP

- Purchase of SOP-complaint Dewar.

Quick Tips for Filling Open Dewars

- Use lab coat, splash goggles, and cryogenic gloves when dispensing liquid nitrogen, and also a face shield if dispensing from a pressured Dewar.

- To prevent filling pipe from moving uncontrollably:

- Increase flow slowly and cautiously.

- Consider using a set up with a fixed rigid filling tube.

- If using a flexible filling tube, fit a diffuser to reduce the reaction force.

- Use a pedestrian barrier if filling in a public area.

Liquid Nitrogen Dispensing – CASE 2

What happened?

Researcher #8 attempted to fill an open Dewar from a pressurized liquid nitrogen tank without using proper PPE. Researcher #8 was wearing a lab coat and using a cryogenic glove, but was not wearing any eye protection.

Liquid Nitrogen Hazards

- Direct contact with liquid nitrogen, cold vapor, or cold metal can freeze tissue and cause frostbite/cold burns.

- Boiling of liquid nitrogen produces large volumes of inert gas which can asphyxiate by displacement of oxygen.

Injury

No, but there was potential for cold burns and eye injuries.

Contributing Factors

- The SOP for liquid nitrogen dispensing had not reached the researcher.

- The researcher was not aware of eye hazards associated with liquid nitrogen filling.

Corrective Actions

- SOP on liquid nitrogen dispensing emailed to all research personnel in the facility.

- Written receipts affirming agreement to follow SOP were collected.

Quick Tips

- Use lab coat, splash goggles, and cryogenic gloves when dispensing liquid nitrogen, and also a face shield if dispensing from a pressured Dewar.

- Use a pedestrian barrier if filling in a public area.